Exploitation of ship ballast water systems has been harming the stability and diversity of marine biodiversity due to invasion by alien organisms and especially the spread of pathogens through microorganisms.

To prevent this, ship ballast water must be treated to remove dirt and harmful microorganisms before being discharged out of the ship. This is the content of the Ballast Water Management Convention (BWMC 2004 – Ballast Water Management Convention) introduced by IMO in 2004 and effective from September 8, 2017 (www.imo.org). Accordingly, based on the timeline when the new IOPPC Certificate is issued, the ship will switch to installing a Ballast Water Treatment System (BWMS) instead of exchanging ballast water before arriving at port (Ballast Water Management System D-2).

BWMS will basically include: Ballast water pumps, filters, microbial processors, sensor and control systems. There are many technologies applied to microbial processors such as using ultraviolet light, electrolysis technology, plasma technology… Outstanding in terms of efficiency and safety in exploitation and operation is the use of electrodes to perform the electrolysis of seawater to destroy harmful microorganisms contained in it.

Requirements when installing the BWMS system include:

- Ballast water treatment equipment must have simple and effective means of operation and control. The control system shall be provided so that the operations necessary for the correct operation of the ballast water treatment equipment are ensured through the necessary automatic systems.

- Ballast water treatment equipment and associated electrical equipment should be explosion-proof if they are intended to be installed in locations where flammable gas atmospheres may be present. Moving parts installed in such locations must be arranged so that static electricity does not form.

- The BWMS must be integrated with an automatic control device that monitors and adjusts the required dose or level of treatment or other parameters of the BWMS on board, which if not directly affecting the treatment, it is also necessary to properly manage the necessary processing.

- The control device must be integrated with a continuous self-monitoring function during the period that the BWMS is operating.

- Monitoring equipment must record normal operation or failure of the BWMS.

- The control device must be able to store data for at least 24 months and must be able to display or print a copy of the recorded data for testing purposes. In situations where control equipment is replaced, means shall be provided to ensure that data recorded prior to replacement remains on board for at least 24 months.

- The control device must be capable of calibrating and re-zeroing the control device’s gauges and must be able to repeat measured values.

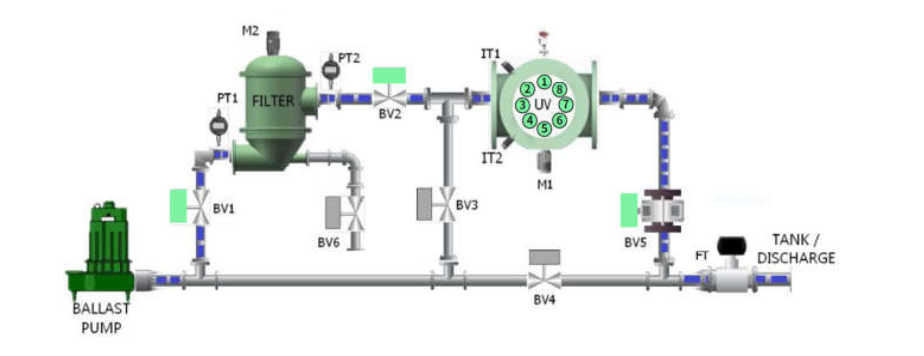

Basic operating modes and principles of BWMS using UV lamps:

Ballasting mode:

Operations:

- On the Mode selection screen to start, select Ballasting mode with the condition that the ballast pump is in ready mode. After selecting the working mode, the filter in/out valves and the UV furnace are fully open.

- Start the ballast pump, wait for the flow to stabilize and meet the settings, then activate the UV light (manually or automatically depending on the settings of each manufacturer).

Water flow direction: Sea water → Filter → Remove impurities and organisms > 50 microns → Automatically clean → Adjust UV light intensity to kill all microorganisms → Enter ballast tank.

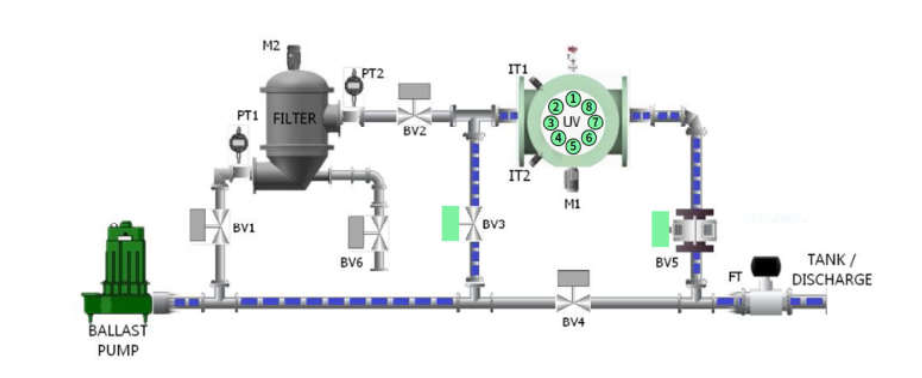

Deballasting mode:

Operations:

- Select Deballasting mode on the monitoring and control panel.

- Observe whether the inlet/system valves are completely open and closed as instructed. With the system in the picture below, Deballasting mode only goes through the UV oven, not through the filter.

- Check whether the ship’s ballast suction valve and side discharge valve are open. When suctioning from a ballast tank, open the valve of that tank.

- Start the ballast pump, wait for the flow to stabilize and meet the settings, then activate the UV light (manually or automatically depending on the settings of each manufacturer).

Water flow direction: Water in ballast tank → Adjust UV to kill microorganisms → Pump into the sea.

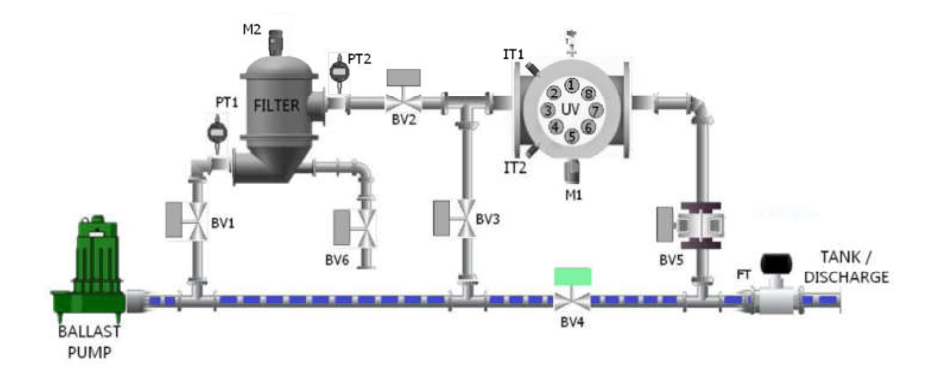

Bypass mode:

Pumping mode without filter and UV furnace is only used when there is a problem or maintenance that requires ballast pumping/ballast discharge. When running the ballast pump along the bypass line, there will be an alarm signal and it will be saved in the system log.

Ballast water treatment systems play an important role in protecting the environment and water resources. It helps reduce water pollution and use water resources effectively, while ensuring safety for people and the environment. To ensure effective use of the ballast water treatment system, it is necessary to comply with the following requirements:

- Shipowners must ensure that the BWMS meets the requirements of the convention with valid certificates.

- Shipowners must ensure that their seafarers are fully equipped with knowledge and training to become familiar with BWMS. Operating procedures must be approved by the Register and updated in SMS.

- Crew members must have a thorough understanding of the system’s structure, principles, and operating procedures.

- After each BWMS is operated, the crew must keep a truthful and complete logbook according to regulations.

With many years of experience in the field of construction and installation of ballast water management systems for ships, from repair ships requiring new installation to new construction ships, Vina TD is proud to be the leading supplier of equipment and services for ballast water management systems in Vietnam.