Air compressors in ships are an important component for providing power to other equipment and systems on board. Air compressors are used to compress air from the surrounding environment into compressed air, creating high pressure for use for many different purposes on ships.

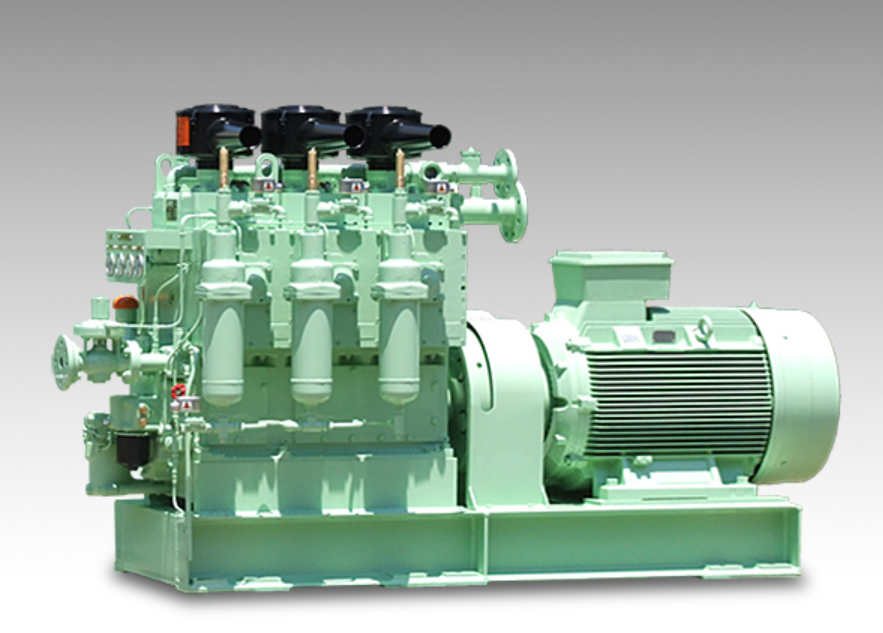

Air compressors on ships are usually powered by an electric motor or diesel engine. The engine pushes pistons to move up and down in a cylinder, creating high pressure in the cylinder and compressing air into compressed gas. The compressed air is then stored in tanks to be used for various purposes on board. Air compressors can be designed to operate continuously or intermittently depending on the vessel’s requirements.

The basic structure of a ship’s air compressor includes: engine, cylinder, piston, suction valve, discharge valve, tank, control system, cooling system and lubrication system.

The role of air compressors in ships:

- Supply air to the ship’s air conditioning and ventilation systems.

- Supply gas for safety and fire fighting systems on board.

- Providing air for the cleaning and sanitation system on board.

- Supplying air to the water injection and wastewater treatment systems on the ship.

- Supply air to other equipment and tools such as cutters, grinders, drills, etc.

Advantages of air compressors in ships:

- Reliable: Air compressors in ships are often designed to operate stably and reliably in harsh marine environments.

- Versatile: Air compressors can supply compressed air to many different systems and equipment on board, from air conditioning systems to tools and other equipment.

- Energy saving: Air compressors in ships are often designed to save energy and optimize performance.

- Easy to operate: Air compressors on ships have a simple structure, are easy to use and operate, helping crew members operate easily.

Disadvantages of air compressors in ships:

- Noise: Air compressors on ships can create loud noise, especially when operating at high pressure, affecting the working environment on the ship and the surrounding environment.

- Space and weight: Air compressors in ships are often large and heavy, requiring space and appropriate infrastructure for installation and operation.

- Maintenance and repair: Air compressors in ships require periodic maintenance and regular repairs to ensure efficient operation and avoid problems.

In addition, safety measures should also be followed to ensure the safety of personnel and vessels.

In summary, air compressors in ships play an important role in providing compressed air for systems and equipment on ships. It helps enhance performance and ensure safe operation of ship systems.

With many years of operation in the field of marine equipment supply, Vina TD can supply air compressors from many different manufacturers, from many different countries such as China, Korea, …