The Ballast Water Management Convention (full name International Convention for the Control and Management of Ships’ Ballast Water and Sediments, 2004) is a treaty adopted by the International Maritime Organization (IMO) in order to help prevent the spread of potentially harmful aquatic organisms and pathogens in ships’ ballast water.

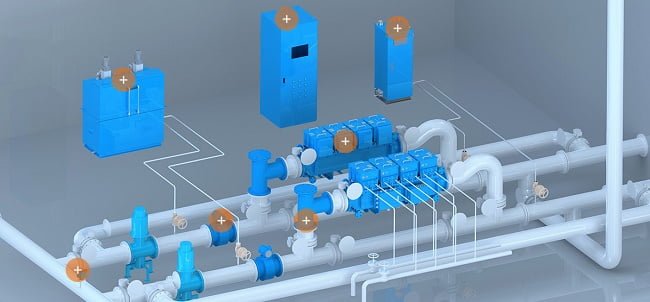

The Ballast Water Management Systems suppling by Vina TD Company Limited uses filtration technology combined with UV treatment. Therefore, the system is highly effective in killing marine organisms and bacteria before discharge ballast water outside the environment. With 100% physical treatment technology, the system can effectively sterilize aquatic organisms and harmful pathogens in the water without generating any toxic substances during ballast and de-ballasting procedure

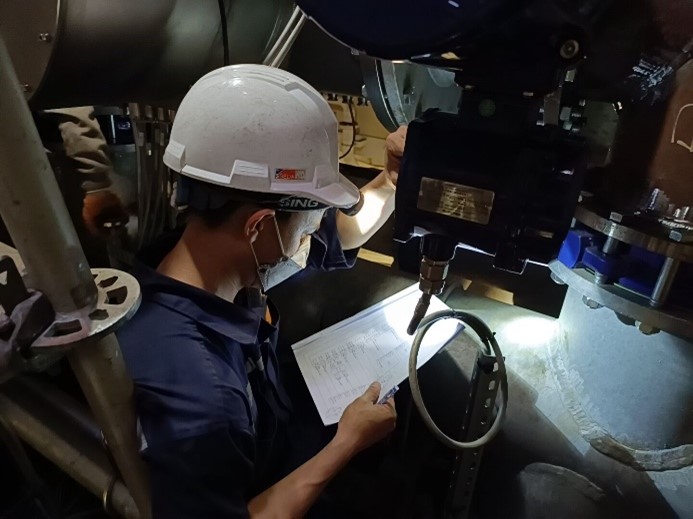

Vina TD Company Limited is proud to be one of the leading company in supplying equipment as well as service such as (installation, commissioning, training,…) for ballast water management system. Especially, commissioning and training for crew members how to operate the system is an essential part for each project. With many years of experience in this field, we are confident our service quality is our strength.

Steps of commissiong and training for Ballast Water Management System:

- Checking the installation according to principle drawings and 3D drawings (if any). Determine the installation arrangement of main equipment, pipeline routes on the vessel, and pipe extraction points into and out of the ship’s old system whether they are correct according to the principle (this will be carried out in parallel from the start of the project implementation to avoid mistakes that lead to repairs later).

- Checking whether the pipe rack positions are arranged accurately according to standards. Checking areas that need additional reinforcement so that the new installed equipment and pipes will be ensured the stability and do not shake when the equipment operates.

- Preliminary check of the electrical part connecting the system, the cable path, the cable trays which are additionally welded, the wire which is belted, the pipe through the wall is sealed with filler as requirement…

- Check cable connections in electrical cabinets and each device (power cables, electric motors, electric valves, sensors, …). Measure the continuity of the wires with an electric meter to ensure the wires are connected correctly according to the drawing.

- Turning on the power of the system after checking and test the system with all modes. Checking all system functions according to the instructions and requirements of the Classification.

- Operating the system when Classification check and support to take the sampling test to analyze ballast water samples.

- Traning and explain to crew members about the principles of the ballast water management system, principle diagram of the new piping system after connecting to the treatment system, how to operate the system control screen, check system alarm functions,…

- Instruct how to handle common problems on system, and steps to checking and maintenance periodically during using the system.

- Hand over relevant documents before ending the project.

Commissioning and training are important and indispensable tasks in every projects of installing BWMS on vessel. Therefore, we always carry out our service in the most standard way. Our mission is not only bring safety service and compliance with regulations but also brings satisfaction in service quality to shipowner.

We will continue to improve the products and services which we provide to bring the best experiences for customers when using our products and services.